Trucks of all varieties need regular maintenance

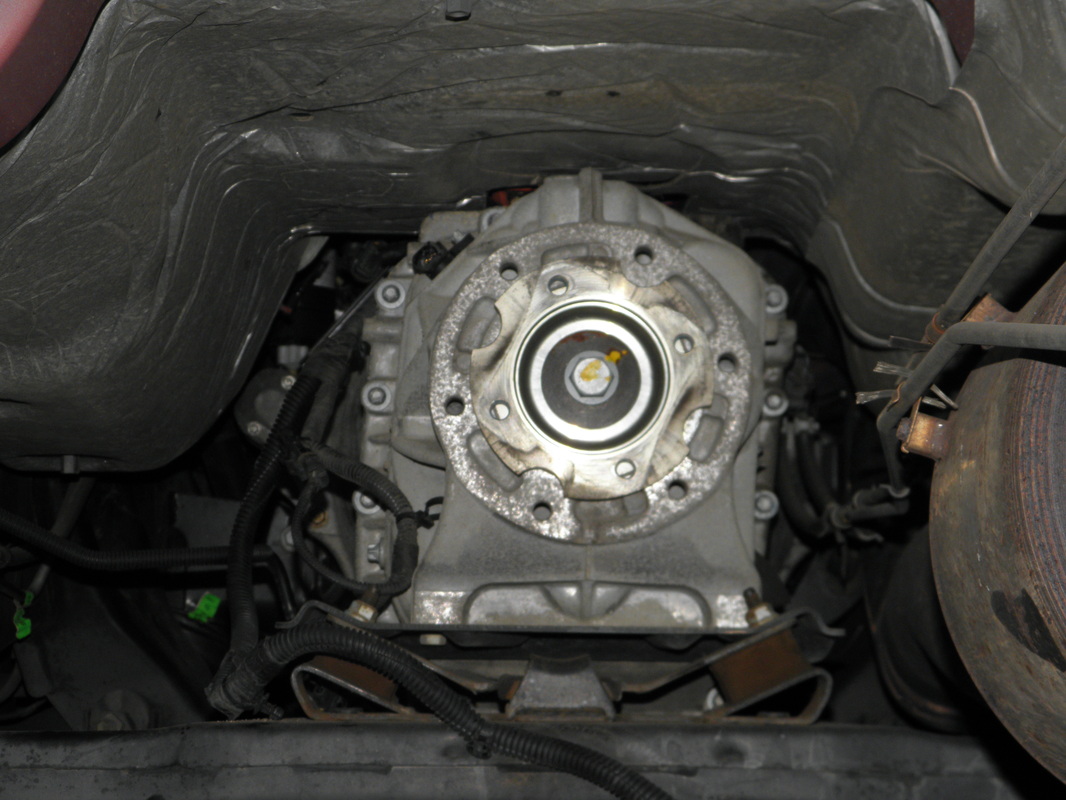

The alternator should be putting out more volts than the battery has, in order to keep the battery charged. If the alternator is generating the same or less than the battery charge, then it is time to change the alternator. Other signs that it is time to change the alternator are:

- A red warning light on dash

- Intermittent red warning light on dash

- Dim lights- most often you will notice the headlights are dim, sometimes the interior lights will also dim

- Slow cranking

- Dead batteries

Another cause to replace your alternator would be if the voltage regulator is overcharging your batteries, causing them to spew acid. In this case the readings on the alternator would register over 14.5 volts.

Nearly all vehicles run on a 12 Volt system and the above standards apply, including all size trucks, semis, cars, motorcycles and boats.

Updated 2/21/14